Additive Manufacturing In Manufacturing Industry

Additive manufacturing (AM), commonly known as 3D printing, has increasingly become a cornerstone in the manufacturing industry, transforming traditional production processes and enabling new possibilities. Below is a detailed exploration of how AM is integrated into the manufacturing industry, its benefits, challenges, applications, and future prospects.

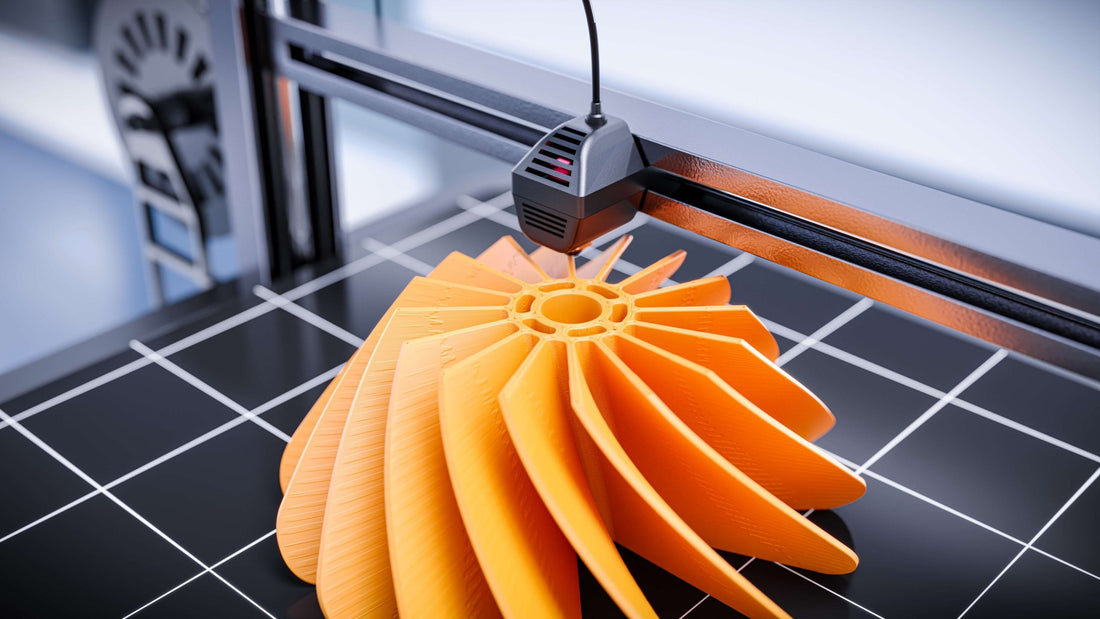

Additive manufacturing involves creating objects by adding material layer by layer, directly from a digital model. Unlike traditional subtractive manufacturing methods, such as machining, which remove material to create shapes, AM builds objects from the ground up, enabling the creation of complex geometries that would be impossible or prohibitively expensive to produce with conventional methods.

Key Applications of Additive Manufacturing in Manufacturing

Prototyping

AM has revolutionized prototyping by significantly reducing the time and cost required to create prototypes. Engineers can quickly iterate designs, test functionality, and refine products before committing to mass production. Beyond simple models, AM enables the creation of functional prototypes made from materials that closely resemble final production materials, allowing for more accurate testing and validation.

Tooling & Fixtures

AM allows for the rapid production of custom tools, jigs, and fixtures tailored to specific manufacturing processes. This capability reduces lead times and costs associated with traditional tooling methods. In injection moulding, AM is used to create Molds with conformal cooling channels, which improve cooling efficiency and reduce cycle times, leading to higher-quality parts and faster production.

Production Parts

AM is ideal for low-volume production runs where traditional manufacturing would be too expensive or inefficient. This is particularly useful for producing specialized components, spare parts, and customized products. AM enables mass customization, where products can be tailored to individual customer specifications without significant cost increases. This is particularly valuable in industries like automotive, aerospace, and consumer goods.

Complex Geometries

AM allows for the creation of intricate lattice structures and optimized designs that reduce weight without sacrificing strength, making it valuable in industries where weight reduction is critical, such as aerospace and automotive. Parts that would typically require multiple components and assembly steps can be printed as a single, integrated unit, reducing assembly costs and improving part reliability.